![]()

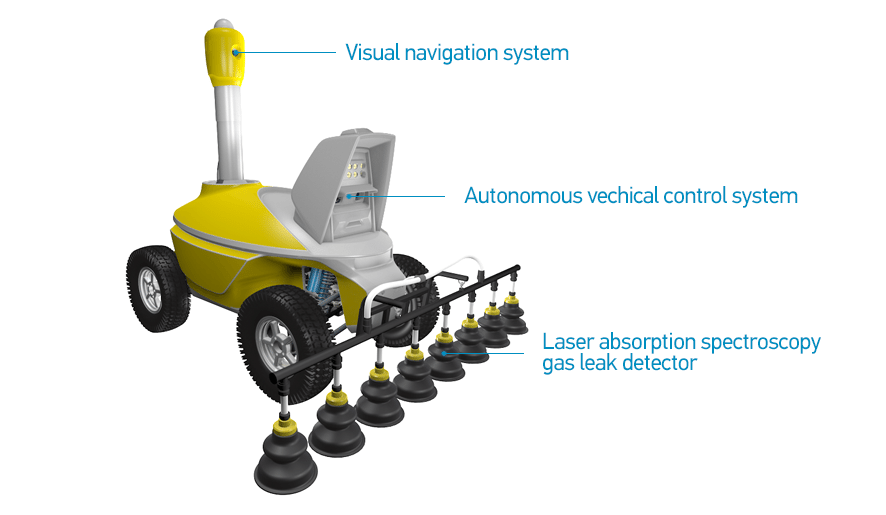

Oil and Gas leak inspection robot

Autonomous Gas Leak Detection Robot S6.3 for Oil & Gas Facilities

Detecting gas and oil leaks is critical to protecting human life and safeguarding investments in equipment at oil and gas facilities.

Traditionally, in addition to stationary gas concentration sensors, this task has relied on human inspectors equipped with handheld gas leak detectors. The S6.3 Mobile Robot replaces this manual role.

The robot autonomously navigates around outdoor equipment at petrochemical sites, stopping at pre-programmed positions to activate its methane detection system. This system includes:

- A pan-tilt platform with a dual camera providing both visible and infrared imaging.

- A remote laser-based methane concentration detector.

By combining the video feed with laser targeting, the robot can direct the methane detector precisely to potential leak points and take accurate measurements.

In this way, the S6.3 robot can automatically inspect dozens or even hundreds of hazardous points for possible leaks. If a leak is detected, the robot immediately sends an alarm signal to the operator.

Human involvement is only required for corrective actions — closing valves, tightening flanges, or repairs. The routine, repetitive work of inspections is handled entirely by the S6.3 robot.

Beyond operational efficiency, adopting mobile robots significantly improves a company’s ESG performance. Robots reduce risks for employees, minimize environmental damage from undetected leaks, and provide auditable data streams that increase transparency for regulators and investors.

Experience in operating an autonomous mobile robot at a petrochemical plant

Underground natural gas pipeline leak detection

The A6 OMD robot, equipped with an optical methane detector, is a perfect solution for underground pipeline gas leak detection. While moving, the robot scans an area of about 6.5 feet wide. Necessary measurements are performed with a close-to-earth scanning beam, which minimizes the impact of wind on the gas concentration. The onboard satellite navigation system ensures an accurate alignment of the robot’s cruise route with the underground gas pipeline corridor. The measurement readings are combined with GPS location data to make up a gas inspection map for a pipeline of any length.

Applications

Petrochemical manufacturer

Compressor station inspections

Plant and industrial Inspections

Gas distribution networks

Gathering pipelines

Underground natural gas pipeline leak detections

Key features

Unmanned gas leak detections

Detection Method – Laser Absorption spectroscopy

Locates methane up to 50 meter away

Infrared gas detection camera

Send request

Attention!

- Deployment of robots and their integration is performed only by SMP Robotics specialists.

- Minimum order: 3 inspection robots

- Minimum service contract term: 3 years