![]()

Electrical Substation Inspection Robot

Thermal Imaging Inspection of High-Voltage Substations

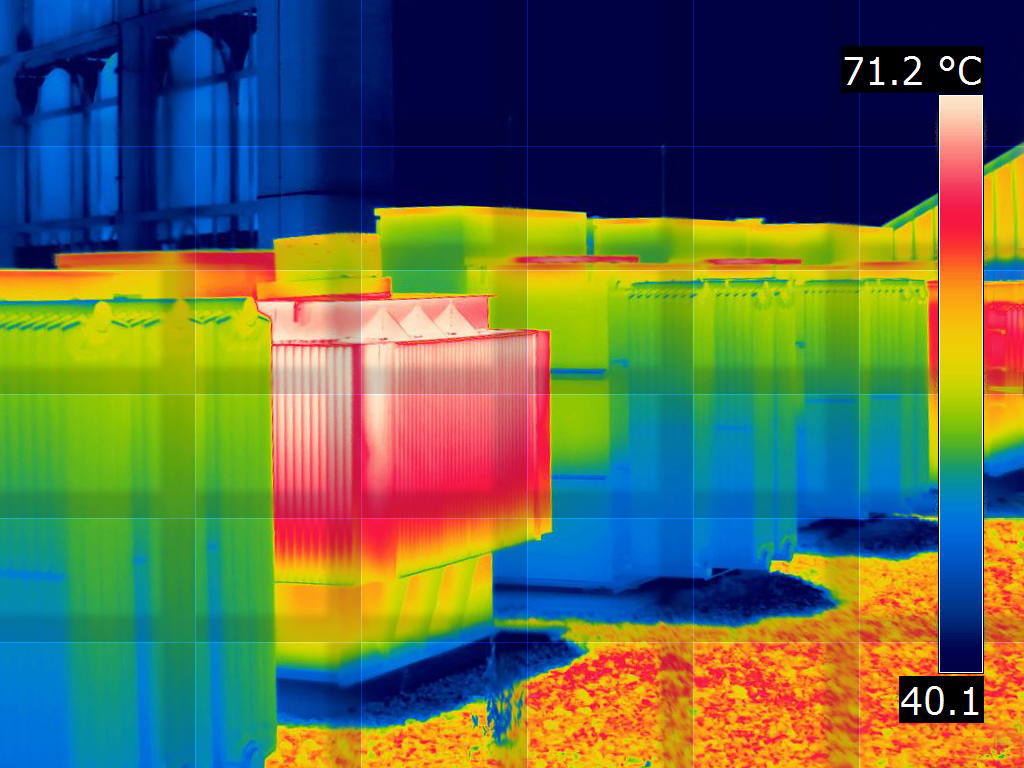

Inspector series autonomous robots are designed for automated thermal imaging inspections of high-voltage equipment installed outdoors at substations (110 kV and above). They detect overheating of contacts, joints, and critical components at early stages—helping prevent failures and unexpected power outages.

Deployed directly on substations, robots follow pre-programmed routes and conduct routine infrared inspections in any weather conditions, including peak load periods. If necessary, operators can remotely launch an unscheduled inspection (for example, after a relay trip) and receive data immediately, without waiting for a field crew. One operator can manage multiple robots across different substations.

Automated Robotic Control of Electrical Equipment

The robot autonomously moves between inspection points, stops, and aims its dual-spectrum thermal camera at high-voltage components, or scans entire assemblies sequentially.

Inspection results—including thermograms, photos, and video—are stored with time stamps, GPS coordinates, and network load parameters. All data is transmitted to the server, creating a digital archive for long-term monitoring and advanced AI-driven analysis of equipment condition, asset health, and predictive maintenance scheduling.

Precision Positioning and Repeatable Thermal Measurements

Unlike manual inspections, the robot captures thermal data from identical points every cycle—same angle, distance, and height. This guarantees fully reproducible inspection conditions.

Such repeatability is essential for artificial intelligence algorithms, enabling detection of abnormal heating patterns and early prediction of equipment failures.

The robots operate 24/7, automatically recharge batteries, and can cover hundreds of inspection points, far beyond the capacity of on-site human surveys. Long-term comparison of thermograms reveals hidden degradation trends months or even years before actual failures occur.

The platform also supports additional sensors:

- UV camera for corona discharge detection,

- directional microphone for partial discharge monitoring.

Infrared Inspection and Site Security in One Platform

The same infrastructure deployed for the Inspector robot (charging station, precision navigation system) can support security robots on substation grounds.

Security robots autonomously patrol fenced areas, deter intruders with audio warnings, and provide photo and video evidence of unauthorized access. This dual-use approach increases both operational safety and physical security of energy assets.

Autonomous Robots for Utilities: Reliability and ESG Impact

Inspector robots are an ideal solution for unmanned, remote, and hard-to-reach power facilities.

- Fully autonomous thermal inspections

- Reliable all-weather operation

- Minimal maintenance requirements

- Reduced OPEX and increased equipment reliability

In addition, autonomous robots contribute to ESG goals by improving workplace safety, reducing environmental risks, and ensuring compliance with modern sustainability standards.

Applications

Autonomous substation inspection (110 kV+)

Solar power plant inspection

Industrial predictive maintenance

High-voltage equipment monitoring

Key features

Autonomous inspection robot for unattended substations

High-accuracy infrared thermography with repeatable data points

24/7 automated operation with navigation and charging

Thermal imaging + video surveillance day and night

AI-ready digital archive for predictive maintenance

Options

UV camera for corona discharge detection

Directional microphone for partial discharge monitoring

Ultrasound inspection module for high-voltage assets

AI-powered gauge reader for automated data capture

Protective shelter + charging station for extreme climates

Send request

Electrical substation inspection

Automated thermal imaging & infrared inspection for remote monitoring

The 2020 model provides for the installation of three types of PTZ cameras from different manufacturers. This helps to avoid the export restrictions of several countries. Also, the list of additional equipment installed on the robot has been expanded. By the request, and installation of a highly sensitive microphone, an ultraviolet camera, weather sensors, the multi-gas detector is available. To operate on the territory of electrical substations, the robot is equipped with a metal fence detector as standard. The robot has a body made of Fiberglass and has a coating that protects against strong electromagnetic fields, this allows you to use it in close proximity to high-voltage equipment and electrical lines.

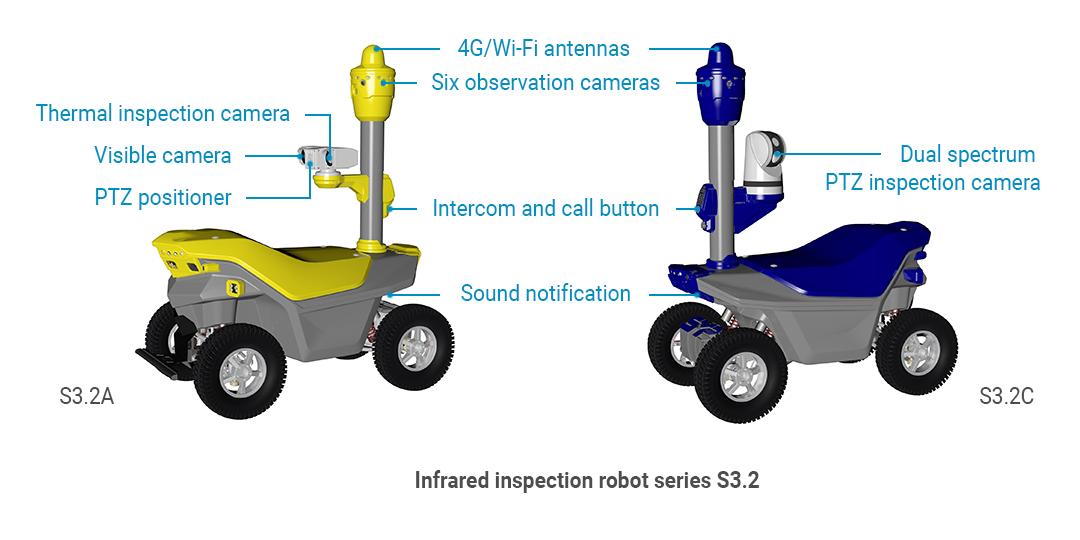

Electrical equipment Inspection robot S3.2

Thermography inspection & video observation

To monitor the work of the robot and conduct security patrols, it is equipped with six circular video surveillance cameras. The cameras have high resolution and allow you to inspect the territory along the path of the inspection route. The image from these cameras is analyzed by a separate on-board computer of a panoramic video surveillance system for detecting people. If they are detected, a two-way voice, communication can be established by using the intercom integrated in the robot.

Video transmission from the robot, information about its location, and operation of systems are carried out via 4G or Wi-Fi wireless channels. The status and location of robots on inspection routes are displayed in the web-based service for group monitoring of the operation of robots.

Applications

Electrical substation inspection

Solar power plant inspection

Commercial infrared thermography

Electrical equipment infrared Inspection

Power generation and heating plants (thermography motors, pump, transformer)

Electrical high-voltage power and distribution devices

Key features

Automated unmanned inspection of unattended facilities

High accuracy infrared thermography

Day/night fully autonomous movement

High-resolution video observation

Automatic charger station

Options

Omni direct or hi sensitive directional microphone

Embedded DSP computer for airborne ultrasound Inspection of electricity equipment

Deep learning embedded computer for gauge reader

Shelter for extra-strong temperature environment and protection from the dust storm

UV camera for detection corona discharge

Mobile whether station

Multi gas detectors

Thermal Image Inspection Robot

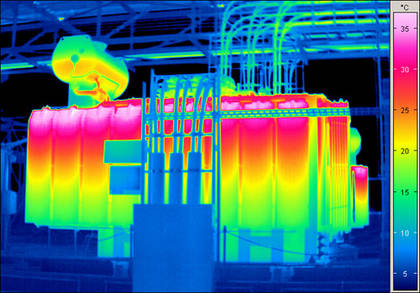

Auditing power equipment temperature is an effective way to prevent accidents at electrical substations and power grids.

Normally, this task is carried out by a qualified technician who uses a portable thermal vision camera to measure the IR emission intensity of the equipment, thus determine its heat rate.

To prevent accidents, this temperature audit should be conducted on a regular basis.

In some climatic regions, the audit of power equipment is performed in the early morning, when the equipment is covered with atmospheric condensation.

The S3 Mobile Robot has a flexible thermal vision camera and is designed for automated auditing of substation facilities’ power equipment temperatures.

Maintaining trained staff to regularly and safely audit all necessary equipment is costly as an expense that can be eliminated. Additionally, safety is increased with the use of the S3 Mobile Robot as hands-free remote diagnostics at unmanned electrical substations can be collected. If any unsafe conditions were to arise, off-site personnel can be alerted before any person comes into harm’s way.

Outfitted with an automated guidance system, the S3 robot navigates through the entire area of a substation and performs on-the-go scanning of the area’s power equipment with the robot’s onboard pan-tilt, positioner-mounted thermal vision camera.

If above-normal temperature is detected, the IR image processing system identifies an overheat and transmits an alarm signal, along with the thermal image, to an operator via WiFi.

The S3 series robots enable remote visual inspection of the equipment in case of a substation failure or electrical accidents therein. This precludes the risk of electric shock for electrical substation inspection technicians. Remote inspection of the substation equipment can provide reliable information before the repair team arrives. The new S3.2 robot for electrical substation inspection has fiberglass mast and body, is fitted with high-profile rubber tires. The robot’s overall height is less than that of an average human being. These solutions enhance the robot electrical safety

The inspection robot can optionally be equipped with an UV camera. UV inspection enables to detect high voltage corona phenomenon invisible to the naked human eye. Corona discharges cause power loss and damage to the surrounding hardware. Timely detection and containment of corona discharges will help preclude a substation failure and carry out timely electrical equipment maintenance.

Purchase and operation of an S3 will cost you a hundred times less than any possible losses incurred due to the facilities’ malfunction and damages caused to the electrical power’s consumers and suppliers.

Given all of these economical and safety benefits, the S3 robot is recommended as a standard component for unmanned electrical substations.

Mobile inspection robot

Positioning accuracy of the robot in front of the object of inspection

Accuracy of automated positioning of the robot at a site for remote inspection:

- R 2.6 ft using visual navigation

- R 38.3 yds using RFID tags

Pointing accuracy at the inspection object from a distance of 7-15 yards with automated positioning the robot at a site for inspection:

- 3-6 degrees horizontally using visual recognition of the inspection object

- 2-3 degrees vertically using visual recognition of the inspection object

- 1-2 degrees horizontally using visual marks of the inspection object by QR code size of 8×8 (in)

- 2-3 degrees vertically using visual marks of the inspection object by QR code size of 8×8 (in)

Thermal scanning time of objects with a higher resolution than that of the thermographic camera

Scanning time of the inspection object 6×6 with 15% overlap of cameras’ fields of view

- 110 sec using visual methods for recognition of inspection object

- 118 sec using visual marks for recognition of inspection object by QR code size of 8×8 (in)

Note: The camera takes pictures, and every time a picture is taken, the camera moves by 85% of the previous frame (generating a 15% overlap). This makes it possible to increase the resolution of the final image. After scanning by thermal imager (resolution 320×240) the final image will be ((320 × 240 × 0.85) × 6) × 6

Additional options

Computer module for three-dimensional temperature model image of the inspected object.

Note: Using two-dimensional images taken from several different positions, the computer module can create a three-dimensional model image that the operator can rotate on the computer screen to see all the details. This computer module is the subject of a major development.

Electric energy consumption of the robot during thermal inspection

- Number of positions around the inspection object: 6 — 24

- Standard consumption using the optional module for a 3D model restoration of the inspected object: 240 W

- Standard speed of the robot: 2.5 mph

- Standard consumption of the robot movement: 600 W

- Standard consumption of the robot during inspection: 90 W

- Batteries: 2×12V 110 A/h

Thermal image made after scanning with the thermographic camera