Robotics Solutions for Chemical Plants, Oil & Gas Facilities

Robots Driving ESG Performance in Oil & Gas and Chemical Plants

Autonomous mobile robots at petrochemical and chemical facilities are transforming the way routine outdoor tasks are handled. By replacing manual patrols and inspections, robots reduce dependency on human labor, cut operational costs, and ensure consistent control over critical processes.

Beyond efficiency, mobile robots directly contribute to ESG performance. They improve Environmental indicators by enabling continuous monitoring of air quality, emissions, and potential leaks, helping companies meet stricter environmental regulations. Socially, they reduce health risks for personnel by minimizing exposure to hazardous areas, while maintaining safety standards across large facilities. From a Governance perspective, robots provide transparent, verifiable data for compliance audits and investor reporting, strengthening corporate accountability.

The use of robotics makes operations not only safer and more predictable, but also more attractive for investors who increasingly prioritize sustainability and risk management. This combination of automation, safety, and ESG alignment positions autonomous robots as an essential part of the future industrial infrastructure.

Key Sites for Robot Deployment in Oil & Gas

Autonomous mobile robots bring the greatest value at:

- Oil Refineries – patrols, inspections, gas detection.

- Gas Compressor Stations – leak monitoring and safety control.

- Petrochemical Plants – video surveillance and thermal scanning.

- Underground Gas Storage – methane detection and perimeter patrols.

- Marine Oil Terminals – security and bird control in coastal zones.

Robots reduce risks, cut costs, and improve ESG compliance.

Autonomous Robots for Gas Leak Detection

Gas leak detection is a critical task for ensuring the safety of people, equipment, and the environment in the oil and gas industry.

The S6.3 autonomous robot automates routine inspections of open-air equipment and pipeline routes, detecting leaks without direct human involvement. By continuously monitoring high-risk zones, the robot reduces operational risks, cuts inspection costs, and ensures faster response to potential incidents.

Using mobile robots for leak detection not only improves industrial safety, but also enhances ESG performance by reducing environmental impact and increasing transparency for regulators and investors

Thermal Imaging Robots for Equipment Monitoring

Thermal imaging is one of the most effective ways to monitor the condition of critical equipment at chemical plants, refineries, and energy facilities. By detecting abnormal heat patterns early, it helps prevent accidents, equipment failures, and costly downtime.

The S3.3 Thermal Imaging Inspection Robot automates this process. Equipped with both infrared and optical cameras on a pan-tilt unit, it performs continuous scans of pipelines, electrical systems, and machinery without human involvement. Its autonomous navigation system guides the robot between inspection points, capturing images in two spectra simultaneously.

Such robots are especially valuable in hot climates, where equipment often operates under high thermal stress. S3.3 units have already been in operation for years at Saudi Electric Company, proving their reliability and efficiency. When abnormal heating is detected, the robot transmits combined thermal and visual data to the control center, enabling rapid operator response and ensuring stable, safe operations.

Eco Robots for Air Quality and Environmental Monitoring

Monitoring atmospheric pollution and greenhouse gas emissions is a critical task for sustainable industrial development. Autonomous mobile robots equipped with advanced air analyzers measure concentrations of harmful substances and CO₂ directly in the field, providing reliable data for environmental safety and compliance with ESG goals.

Unlike stationary monitoring stations, the S2.3 Eco Robot collects data along its entire patrol route. By adapting its path to weather conditions, wind direction, and local pollution levels, it creates a detailed and dynamic picture of air quality across large industrial zones. This enables early detection of harmful emissions and helps companies reduce their environmental footprint.

A single S2.3 Eco Robot can replace several stationary stations, delivering broader coverage at a significantly lower cost. With electric drive, long service life, and full autonomy, these robots support UN Sustainable Development Goals by reducing greenhouse gas emissions and providing actionable data for regulators, investors, and local communities.

Gas Detection Robots for Industrial Safety

Monitoring air quality and gas concentrations at oil, gas, and chemical facilities is critical for protecting workers, the environment, and production assets. Early detection of hazardous gases not only prevents accidents but also ensures compliance with strict safety and ESG standards.

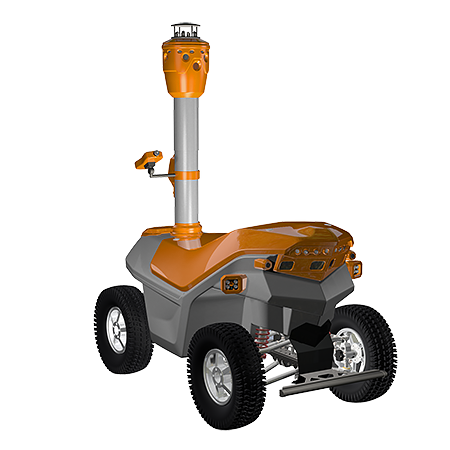

The S2.3 Gas Detector Robot automates this process by carrying multi-gas analyzers on its mast and patrolling factory perimeters and equipment zones without human presence. During its route, the robot stops at control points to take precise measurements and transmits results wirelessly to the central monitoring system. Its autonomous navigation system avoids obstacles and automatically returns to the charging dock when needed.

Unlike human inspectors, the robot can safely operate in areas with toxic or explosive gas concentrations for extended periods of time. This makes it especially valuable for continuous monitoring of large industrial sites. By providing real-time, reliable environmental data, the S2.3 Gas Detector Robot reduces risks, improves worker safety, and supports sustainable operations.

Sample Transport Robots for Industrial Facilities

Regular sampling is a vital part of many industrial processes, but moving samples between collection points and laboratories often requires staff to walk long distances or rely on vehicle transport. The S5.2 Prompt robot automates this routine task, ensuring timely and reliable delivery without human involvement.

The robot follows a pre-scheduled route, automatically starting transport once samples are loaded. With integrated voice control powered by Large Language Model (LLM) technology, staff can assign or adjust tasks simply by speaking to the robot. This flexibility makes it easy to manage unscheduled or repeat sampling requests directly on site.

Beyond logistics, Prompt can also serve as an intelligent assistant — guiding visitor around a facility or providing information about operations, using a locally hosted AI model trained on customer-specific data.

When not in use, the robot remains in its shelter, recharging autonomously and ready for the next assignment. By automating routine transport, Prompt reduces labor costs, increases efficiency, and ensures full traceability of critical sampling operations.

Proven 24/7 Security: Autonomous Robots for Industrial Facilities

Perimeter protection and site surveillance are among the most demanding tasks for any industrial facility. Traditional guarding requires large teams of staff working in shifts, with high costs and the constant risk of human error. The S5.3 Argus robot automates perimeter patrols and video monitoring, providing 24/7 security coverage with unmatched reliability.

Equipped with six panoramic cameras and a PTZ unit with thermal vision, Argus detects and tracks people even in complete darkness, beyond fences and in remote areas. Integrated AI enables real-time human detection, facial recognition, and automatic alerts to the control center. The robot also features a built-in loudspeaker for warnings and an intercom for direct dialogue with people on site.

Operating autonomously, Argus patrols programmed routes, avoids obstacles, and returns to its docking station for automatic charging. With all-weather design and long runtime, it can secure facilities in rain, snow, or extreme temperatures. The model has been successfully operating for many years at Eni oil refineries in Italy, proving its reliability in demanding industrial conditions.

By integrating seamlessly with ONVIF-compatible VMS systems, the S5.3 Argus becomes a scalable solution for modern security infrastructure — reducing costs, improving safety, and strengthening ESG performance by lowering risks, protecting employees, and increasing transparency for regulators and investors.

Security provision at petrochemical facilities

Stable and safe operation of petrochemical facilities is impossible without ensuring physical safety right within their areas. For big enterprises, this objective requires the services of numerous security guards.

Autonomous security robots produced by SMP Robotics will help improve the security with fewer personnel, as follows:

The S5 Perimeter Patrolling Robot helps maintain control over the petrochemical facility perimeter. The S5 HD Robot is designed for remote video surveillance of equipment locations and personnel areas. The S5 PTZ Robot is capable of mobile video surveillance of the area adjacent to the gas facility. The S5 ALPR Robot, equipped with an automatic license plate detector, is capable of an automatic control of cars parked on the enterprise’s premises.

Autonomous Bird Control Robots for Coastal Petrochemical Facilities

Bird activity is a constant challenge for petrochemical plants, especially in coastal areas where large flocks can damage equipment, contaminate storage tanks, and spread pollutants during oil spills. In addition to economic losses, uncontrolled bird presence creates serious environmental and safety risks.

The S4.2 Bird Control Robot offers a mobile, autonomous solution. Unlike stationary scaring systems, it patrols large areas along perimeters and shorelines, creating a moving barrier that keeps birds away from critical infrastructure. The robot follows a programmed route, adapts to site conditions, and can operate continuously thanks to automatic recharging or optional solar modules.

These robots have already proven effective in minimizing bird-related risks at industrial facilities, ensuring reliable protection of equipment and the surrounding environment with minimal human involvement.

Gas detector robot

Gas detector robot Oil and Gas leak inspection robot

Oil and Gas leak inspection robot Thermal Imaging Inspection Robot S3

Thermal Imaging Inspection Robot S3 Autonomous delivery robot Prompt 2021

Autonomous delivery robot Prompt 2021 Thermal security robot S5.2 IR Argus

Thermal security robot S5.2 IR Argus S5.2 Security guard robot

S5.2 Security guard robot Bird Scaring Propane Gun Robot S9

Bird Scaring Propane Gun Robot S9