Autonomous Mobile Robot and Unmanned Ground Vehicles

For more than three years, “SMP Robotics” has produced S-series robots. The autonomous mobile robots of this series include several models. All models of this series have the same transport system and differ in additional onboard equipment. Additional equipment can solve tasks that are not related to the automatic movement of the robot. That equipment is responsible for the following tasks:

- Security of area by means of an intelligent video surveillance system;

- Transportation of small parcel in an automatically locked compartment;

- Inspection of industrial facilities using thermal cameras and gas detectors.

Listed applications are based on the ability of the robot’s transport system to autonomously move along a predetermined route and avoid obstacles. Safely navigate the route during the day, in bright sun, and at night, possibly in complete darkness. Confident to navigate in different weather conditions such as rain and snow. The use of a unified transport system for all models of S-series robots allowed accumulating experience in using robots on a variety of routes. In 2021, a number of automatic motion control systems of robots have undergone a deep modernization that has increased their efficiency and usability.

New electronics of Autonomous Mobile Robot AMR 2021

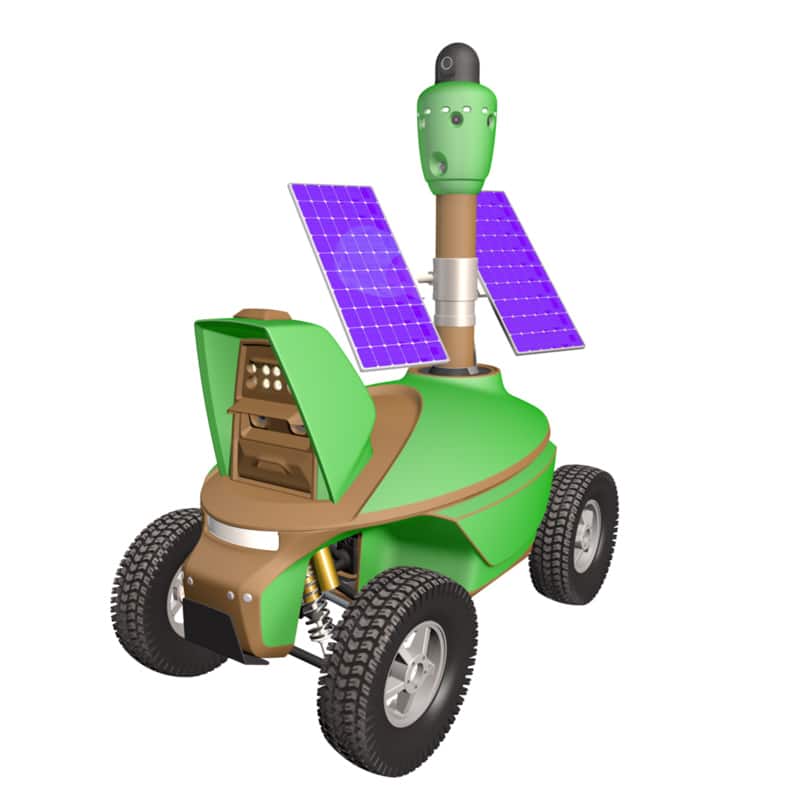

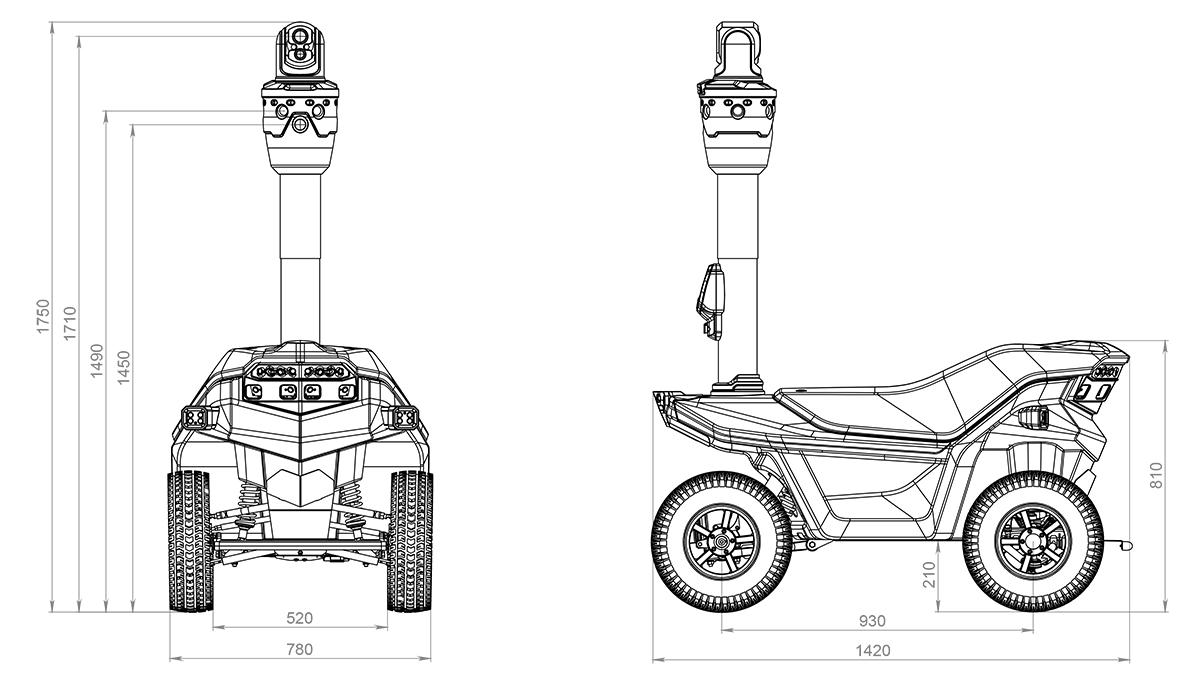

It is noteworthy that in the new robots, the upgrade affected only electronics and software. The design of the robot has remained unchanged for several years due to its reliability and efficiency. It provides reliable movement of robots on road conditions with all types of surfaces and smooth overcoming of small obstacles due to stones, curbs, single steps. The ground clearance allows the robot to overcome small puddles without the risk of damaging the electronics. The smooth running of the chassis is sufficient for video surveillance and inspection on the move. However, it must be clearly understood that the S-series robots are designed to move on paved roads. A-series of robots is designed for movement on all types of roads, including unpaved and covered with snow. These robots are in the testing stage.

Powerful docking station for fast charging of mobile robots

For the multi-day autonomous operation of the robot, automatic charging stations are supplied. They allow robots to work without human intervention in uninhabited objects. Robots that are supplied from the second half of 2021 are designed for a higher charging current than before. This made it possible to reduce the time of robots full charging by one and a half times.

Onboard supercomputers in all robot models

Application tasks, that robots are designed to solve require a high level of analytics. In this case, the true autonomy of the robot is achieved only if the data processing is carried out on the robot’s board, and not on a remote server or in the Internet cloud. For these purposes, all robot models are equipped with an embedded supercomputer based on the Jetson TX2 processor. This processor provides the analysis of images from numerous cameras of the robot and the extraction of information of interest through the use of Deep Leaning algorithms. The robot’s onboard computers have phenomenally low power consumption and high computing performance. The processor architecture is optimized for working with neural networks, which have proven their high efficiency for solving tasks of recognition and classification of video and audio information.

The artificial intelligence of unmanned ground vehicle

In the process of the real, long-term operation of robots, a class of problems emerged that cannot be solved by traditional programming methods. To solve them, a software training module with AI elements was developed. It allows forming the features of the behavior of robots inherent to a particular territory on which the robots are used. The AI module allows the robot to acquire individuality and fine-tune it to the uniqueness of the tasks being solved. It is noteworthy that the AI software module has a voice interface, which significantly facilitates its learning. Currently, the AI module is in limited implementation. However, it is obvious that the future of robots that work in the human environment lies precisely in the development of their artificial intelligence.

2021

2019

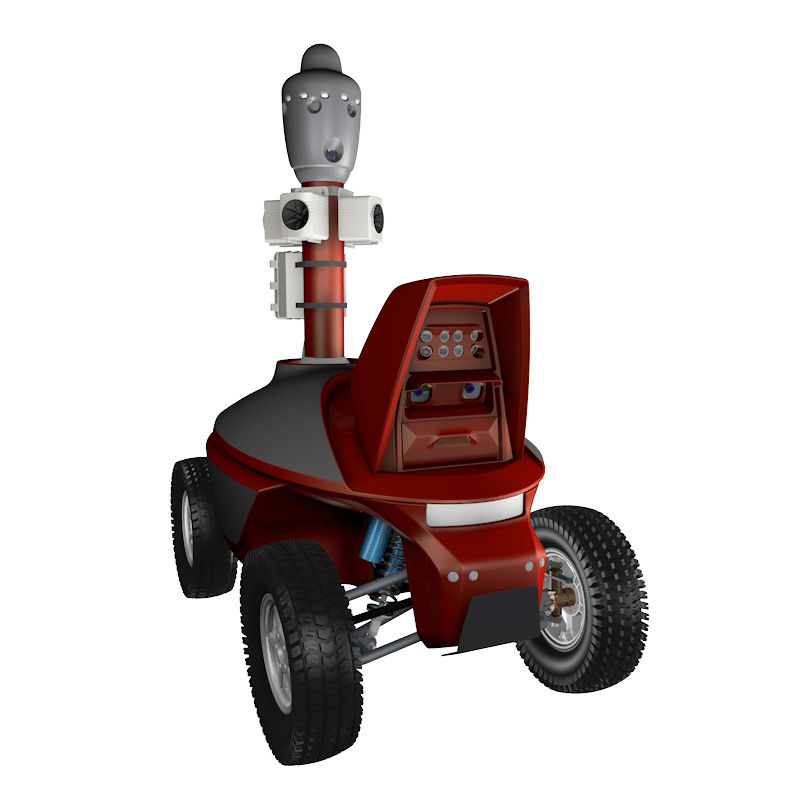

In 2019 SMP Robotics company started to ship the second generation of S series robots — Sхх.2. The new generation of autonomous mobile robots is a huge step in developing automation technologies for outdoor security and inspection tasks.

The next generation platform serves as a basis of S3.2, S5.2, S6.2, S7.2 robot models. Unlike the previous models, these robots are produced in series. They are currently being certified in accordance with the legal requirements that exist in the countries where our consumers are located.

These new models feature a significantly reworked construction. A mobile robot has a fully closed hardware section. This allowed us to achieve high levels of moisture and dust resistance and reduce electromagnetic emission. Besides, a double casing solution was implemented that helps to reduce direct sunlight-induced heating inside the robot. This solution improved thermal regimes of the electronic equipment and reduced the risk of overheating. The autonomous motion control system has undergone some exciting improvements. To learn more about those changes, visit the technology description page.

Artificial intelligence for unmanned ground vehicles (UGVs)

The robots that feature an on-board analytics video system were equipped with a solution powered by NVidia Jetson TX2 supercomputer. This built-in computer makes it possible to process video using deep learning algorithms to perform tasks that require the use of artificial intelligence. The robot’s intelligent video surveillance system is compatible with all famous ONVIF CMS. Such as: Genetec, Milestone, Avigilon, Macroscop.

For the new robots, a range of important options was developed. The most notable option is the auto charging docking station. It allows a robot to charge its battery without any human intervention. The dock station has a wear-resistant mechanism and has successfully passed rigorous endurance tests.

The new robots equipped with sensitive front bumpers can be purchased together with a mesh fence detection feature. This optional feature helps to avoid incidents during the robot’s movement along a mesh fence and reduces the risk of damage caused by small-sized obstacles, such as thick wire or free-standing equipment and structures.

S series robots are powerful enough to move on gravel and concrete roads, however, they are not intended for use in off-road conditions as well as deep snow. The new A series is currently being developed — these robots will be suitable for snowy and off-road conditions, as well as rocky and sandy roads.

Technical specifications S series robots 2021

| Cruising range at +5°C (41°F), up to | 24 km | 15 miles |

| Accuracy of check-point drive-through circle radius | 0.8 m | 2.5’ |

| Minimum illumination for visual navigation | 6 lux | |

| Minimum illumination for obstacle avoided systems | 0 lux | |

| Speed while traveling autonomously | 4 – 6 km/h | 2.5 – 4 mph |

| Width of patrol route path, min | 0.9 m | 3.0’ |

| Turning radius, min | 5 m | 16.4’ |

| Ground Clearance | 14 cm | 5.5″ |

| Climbing Angle | 15° | |

| Dimension | 1420 х 780 х 1750mm | 56″ х 31″ х 52″ |

| Weight (with batteries) | 110 kg | 240 lb |

| Waterproof and dustproof level | IP65 | |

| Operating temperature range | -20°C … +45°C | -4°F … 113°F |

Application

Features

-

Autonomous movement without GPS signals

-

Obstacle avoidance system

-

Automatic charging station

-

High protection from the environment

2019

2017

SMP Robotics specializes in the development and serial production of several types of Autonomous Unmanned Ground Vehicles (UGVs), all of which are used as the basis for special-purpose mobile robots.

A mobile robot consists of two components: the UGV and the special-purpose equipment it carries.

UGVs of all series are equipped with an autonomous guidance system that allows the mobile robot to store its cruise route and move automatically without an operator.

The automatic guidance system operation is based on input from the video cameras, allowing the UGV to accurately follow programmable routes while detecting and avoid obstacles.

All UGVs produced by SMP Robotics have an electronic motor that drives and is powered by built-in accumulator batteries. When low on power, the UGV automatically returns to its maintenance area.

UGVs of different series vary in their mechanical powertrains, which are perfectly suited for different types of roads that our mobile robots may operate on.

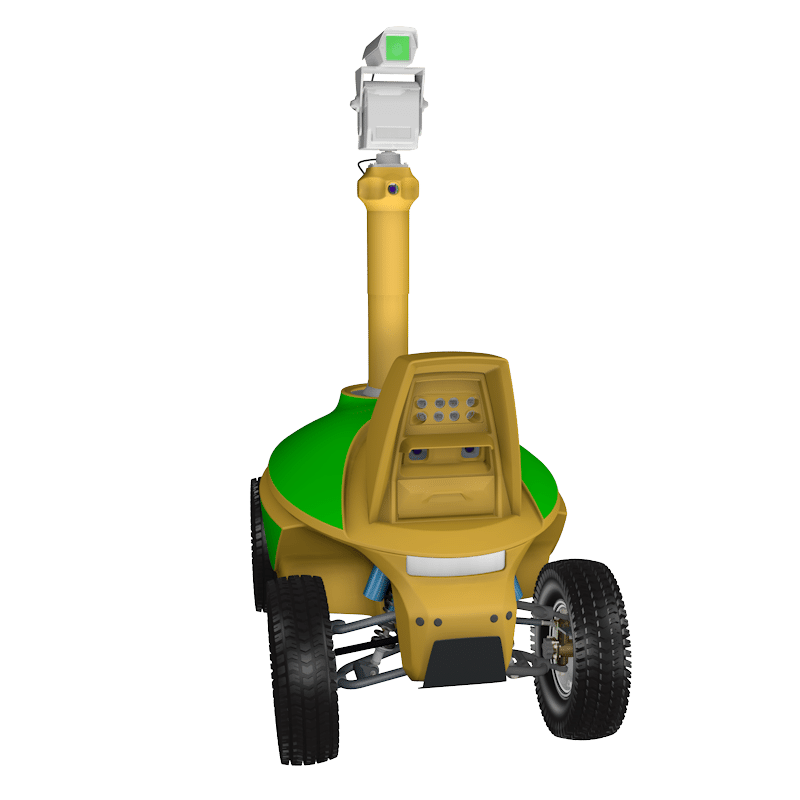

Autonomous UGV S-series for landscaped areas and industrial facilities

This UGV series is designed for roads with good traction characteristics. These UGVs are ideal for landscaped area patrols and inspection of industrial facilities.

The guidance system uses visual navigation and is effective for pathfinding in environments densely filled with artificial structures and hard-surface paths. This Autonomous Unmanned Ground Vehicle can accurately complete routes of up to several kilometers long in areas with no GPS coverage. In case of insufficient lighting from street lamps at night, the UGV uses night markers located along the dark part of its cruise route.

A stereo camera is used for detecting obstacles and finding the optimal way. For the stereo camera to work correctly at night, the robot is equipped with a low beam headlamp, which switches on automatically at dusk.

The UGV S-series powertrain has two built-in accumulator batteries to power its autonomous movement systems. A third battery can be optionally installed for powering carried equipment. Standard size batteries are used, so you can choose those produced by a manufacturer that best suits your needs.

This wheeled robot is propelled by an electric rear transaxle with a differential that drives power efficiently while in motion. The front wheels are free-rolling and equipped with sensors for picking up data along the UGV’s route and for path-motion calculations.

Rear transaxle control is the best solution to ensure a good grip when moving along roads. The passage route should be laid so as to help the mobile robot avoid dirty areas in the rain, as hydroplaning could result. The UGV S-series can operate in hot climates. Special attention has been paid to the UGV’s cooling system, ensuring its operational capability at high temperatures.

Features

- Fine movements on a couple of miles of long-loop routes

- Reliable guidance in case of unstable GPS coverage

- A separate battery for powering carried equipment

- High propulsive efficiency on roads with good traction

- Electric rear transaxle with differential operation

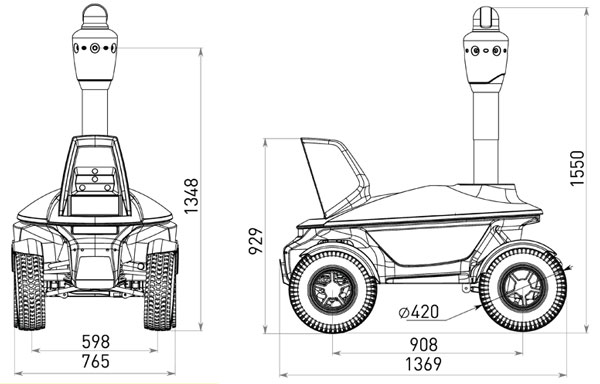

Technical specifications UGV S series 2017

| Patrolling time (60% surveillance and 40% movement), standard | 12 hrs |

| Panoramic cameras placement height | 4.59 ft |

| Cruising range at +41 °F, standard | 15 m |

| Speed of automatic movement, standard | 2.5 mph |

| Optimal cruise route width | 3 ft |

| Optimal turning radius | 17 ft |

| Standard WiFi reach | 1000 ft |

| Standard battery charging time | 4 hrs |

| The range of operating temperatures | -4…+113 °F |

| Dimensions W×D×H | 31.5×55×63 in |

| Weight | 192 lbs |

UGV S-series based mobile robots